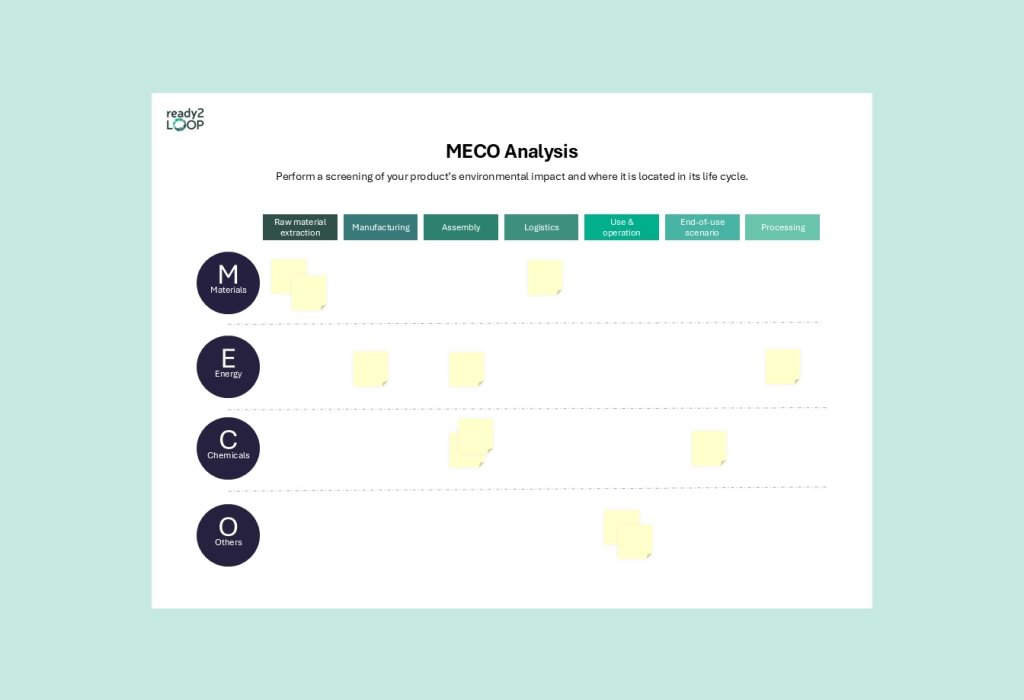

MECO Analysis

Perform a screening of your product’s environmental impact and where it is located in its life cycle.

BEGIN WORKING WITH TOOL

Want to download tools freely?

Click the button and assess your company to access all the tools and to get a customised transition path and tools just for you.

What is the tool about?

A MECO Analysis is a screening of the environmental impact of a product in four categories; Materials, Energy, Chemicals, and Others. The impact is further distributed on at least five stages of a product life cycle; material extraction, manufacturing, transportation, use, and end-of-life.

The valuable outcome

Understanding of the product life cycle of the product and pinpointing of environmental hotspots.

Preparation for use

We recommend that you familiarise yourself with the approach around a MECO analysis e.g. by reading the source article that gives a practical guide to life cycle screening.

We recommend that you have created a functional unit (use e.g., ‘Defining a functional unit’ from the website) and conducted a mapping of material flows (use e.g., ‘Materials Flow Analysis (MFA)’) before conducting the following analysis.

Preparation Time: 0-2 hour(s) depending on your level of experience.

Competencies involved: Sector-specific knowledge, life cycle thinking, technology, business development

Tool kit: Print the tools in A3 and lay out the life cycle stages and the MECO-categories on a table or stick it to the wall. See example in tool.

The steps to take

We recommend you to have created a functional unit and conducted a mapping of material flows (e.g. product life cycle mapping or material flow analysis) before taking the following steps:

Step 1: Agree on the scope of the MECO Analysis (1 hour):

- Is it to gain a preliminary understanding of where in the system different environmental impacts occur?

- Or is it to make a quantitative screening and to identify hotspots?

- How precise do you need the screening to be to be comfortable with the results?

Step 2: Discuss the environmental impacts of the product and allocate the impact to the life cycle stage for which it occurs (2-3 hours)

Step 3: Next, split the environmental impact into the four MECO categories; Materials, Energy, Chemicals, and Others (1hour).

Step 4: Review and discuss the table (2 hours):

- Where do the top 5 impacts seem to occur (hotspots)?

- Is that something that you can change?

Consider if you are satisfied with the degree of detail to proceed or if you need to quantify the impacts.

Step 5 (Optional): Need to quantify the impacts? You can either to it manually by e.g., following the calculation methods presented in ‘Håndbog I miljøvurdering’ or use a simplified Life Cycle Assessment tool e.g. CES Eco Audit.

Step 6: Discuss how you can minimise the environmental impacts. What circular design or business strategies will be most effective to minimise the environmental impacts?

Total co-creation time: 2-7 hours.

Setting: Workshops, desktop research, and possibly audits.

Keywords

life-cycle; life-cycle check; meco; product life-cycle; screening; materials; energy; chemicals;

Source article

Title: Product Life Cycle Check: a guide

Authored by Henrik Wenzel and Nina Caspersen, Institute for Product Development, Anders Schmidt, dk-TEKNIK Special edition adapted for course 42372, Tech.University of Denmark by dr. Michael Hauschild, September 2000.

Decision level

- Strategic

- Tactical

- Operational

Participation

- Individual

- Team

Phase of transition path

- Explore strategic opportunities

- Define direction

- Develop initiative

- Evaluate & plan implementation