Value recovery by closing the loop with a ‘Product-service system’ implementation and recirculation of industrial tempering machines

"We aim to develop more circular business models because we want to reduce our impact on resource use and because we believe that it will be an increasingly good business. Digitalization and PSS are first in line. We believe that at some point in the future, we will benefit from applying EoL strategies for our products, making the best use of the value of the product, parts, and materials."—Jesper Jerlang, Sustainability Manager.

Opportunity

Aasted has no access to the customers’ decisions on handling the products at the End of Life. Bridging this gap could potentially create value by recirculating machines and tapping into the potential market for reuse, refurbishment, and remanufacturing. This correlates well with their current ambition of integrating IoT and predictive maintenance. Their plan for piloting a product-service system (PSS) may financially incentivize a takeback system while entering new markets.

Path

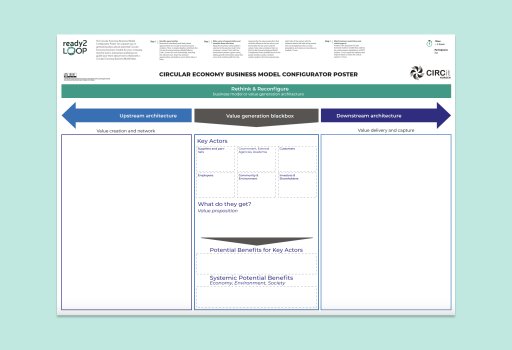

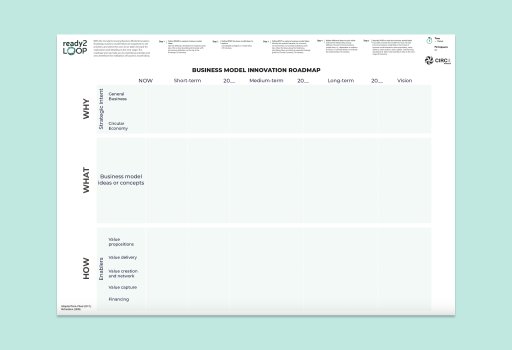

To enable a transition to a Circular Economy in the EoU/EoL of the tempering machines, several initiatives are needed. The 'Circular Economy Business Model Innovation Roadmap' details pre-PSS piloting initiatives and actions in the customer use phase and ensures the necessary CE strategies to recirculate the tempering machines and tap into the second-hand market. Additionally, IoT integration can support the continuous improvement of the design for recirculation.

Outcome

The outcome is a functioning PSS for the tempering machines coupled with EoU/EoL strategies overseeing the recirculation of the machines and components through direct reuse, refurbishment, or remanufacturing. Aasted will become familiar with utilizing IoT solutions for maintenance and optimization in the use phase of their machines. The experience with the PSS and EoU/EoL management will be a stepping stone towards upscaling their CE initiatives to encompass other product lines and strategies.

Context

Aasted is a machine manufacturer specialising in chocolate production. The project scope considers chocolate tempering machines in Europe. Aasted’s ambition is to lead the transition towards sustainable chocolate production, improving its circularity as one of its core strategies. Currently, their Circular Economy efforts are related to enhancing energy efficiency and increasing product lifetime through life-extension services such as maintenance, guidance, provision of original spare parts, and repair. These add-on services currently constitute a large part of their business model. Recommendations from a PhD project with DTU have sparked their interest in piloting a “product-as-a-service” model (PSS) for tempering machines. This PSS initiative serves as a gateway to further explore connecting Circular Economy strategies, such as reusing, refurbishing, or remanufacturing, for implementing and handling an End-of-Use (EoU) system.

Opportunity

Aasted has currently focused its CE initiatives on the use phase to increase the lifetime by introducing a modular design and durable construction suited for maintenance. However, as customers are solely responsible for End-of-Life (EoL) management, there is still little knowledge of what happens to the machine. Despite this, it has been identified that Aasted’s tempering machines have value in EoU and/or EoL, reflected in customers reselling the machines for reuse, remanufacturing, or recycling. This market presents a good business opportunity for Aasted due to its strong channels and customer relationships. This may be leveraged with Aasted’s current ambition of integrating smart systems for predictive maintenance and the PSS pilot. The opportunity thus lies in the potential interest in the market and financial incentives in takeback systems while extracting the value in the tempering machines to minimize the use of resources.

Transition path

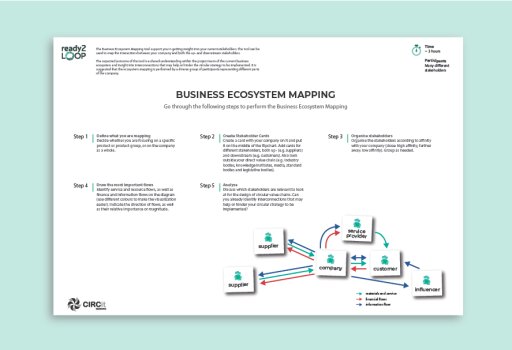

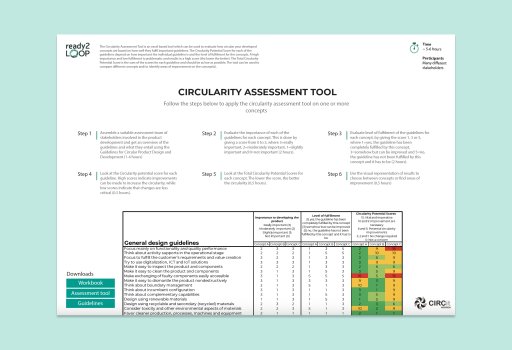

The chosen dimensions depict opportunities for Aasted that involve exploring the handling of EoU to recover the value of the tempering machines while expanding the customer base. Aasted’s current focus on piloting a PSS creates a strong basis for a CE transition. In collaboration with Aasted, two tools were chosen and applied to envision a clear transition: the ‘Recirculation strategy decision tree’ helped identify specific realistic and suitable strategies for the tempering machine after EoU. Direct reuse, refurbishment, and potentially remanufacturing at a product level could be a possibility for Aasted. While Aasted already excels in repair and maintenance, additional capabilities and collaborative partnerships are required to ensure the handling of EoU in-house. A more detailed pathway was described with the use of the ‘Circular Economy Business Model Innovation Roadmap’, laying out initiatives that would be needed: (1) before piloting the PSS, (2) during the use of the tempering machines by the customer, and (3) after the machine is returned to Aasted. Before piloting the PSS, the main initiatives are establishing partnerships with suppliers and logistics, testing suitable locations for takeback centres, and identifying a customer segment interested in PSS, reused machines, and integrated IoT. During the use phase, the next steps entail monitoring the machines with IoT and expanding in-house competencies for refurbishment and remanufacturing. Finally, upon the machines' return to Aasted, they must undergo preparation with an appropriate CE strategy to ensure readiness for the subsequent usage phase. Thus, enhanced IoT input can help support the continuous improvement of the design for recirculation.

Outcome

Aasted's transition to circularity involves implementing a PSS for tempering machines, accompanied by EoU/EoL strategies. Offering diverse customer contracts ensures a steady revenue stream, while refurbishment and remanufacturing competencies extend product lifecycles and minimize resource use. Supplier partnerships facilitate efficient component sourcing and EoL management for refurbishment and remanufacturing and strategic partner collaborations to establish the infrastructure required to streamline reverse logistics. Aasted's entry into the second-hand market offers affordable and sustainable alternatives. Additionally, the company gains valuable insights into PSS implementation, creating a foundation for scaling up circular practices for larger product portfolios and customer bases. This holistic approach positions Aasted as a pioneer in circular business in the chocolate manufacturing industry.

Reflections

Engaging in discussions allowed for a dynamic exchange of ideas. According to Aasted, the accelerator project has been a valuable experience: “There have been good discussions, and it is nice to be challenged. You asked great questions, held onto some ideas, and pointed out some possibilities. So, it has definitely been exciting and rewarding to participate. So, thank you for that!” The accelerator project broadened horizons, positioning Aasted to embrace circularity and create value throughout the product life cycle.

Next step

The next steps for Aasted are to mature and advance the concept by acquiring the necessary competencies, establishing strategic partnerships, leveraging insights gained from their pilot initiatives, and securing customers to initiate the pilot program and, additionally, establishing the logistics and infrastructure required for implementing the PSS and takeback programs to ensure seamless coordination among the partners involved in the takeback value chain links.

Micro-Accelerator. January 2024 - offered by ready2LOOP & DTU Course, Design for Circular Economy

Company

Aasted ApS