Implementation of a pilot takeback system to increase price-tag-holder recyclability

“The Accelerator programme allowed us to learn and gain valuable input to improve our discussions on how to align our take-back activities with circular economy principles. This helps us to contribute to environmental sustainability and stay true to our commitment to responsible business practices.” Primo Group

Opportunity

The implementation of a circular takeback system for price-tag holders has the potential to promote environmental sustainability through the recirculation of material. This provides a potential solution to the long-term challenges of emissions related to raw material sourcing while also contributing to Primo’s ongoing sustainability efforts. A takeback system would also align with the retailers’ desires to find EoL (End-of-Life) solutions.

Path

The first step towards circularity is a pilot take-back system for recycling Primo’s own price-tag holders at EoL. It is crucial that Primo increase downstream communication and establish new relationships with key stakeholders willing to participate in the pilot project. The recycled plastic must be tested to assess whether the quality is suitable for new extrusion, and an assessment is needed after the pilot project to identify opportunities for a future take-back system.

Outcome

Planning the take-back pilot project brought important aspects into light, such as the need for collaboration with key value chain actors and establishing new relationships. Road mapping the take-back system and implementing it in the future will work towards closing the loop and enhancing material recycling, which improves the company’s readiness to become more circular. Primo will enhance their readiness by engaging in planning the pilot project and bringing the ideas into action.

Context

Primo is a leading plastic extrusion company offering the extrusion of customised plastic profiles for clients from a wide range of industries, from heavy industry to sports and leisure. Through the FUTURE FIT program, Primo is committed to increasing its sustainability efforts. The company joined Ready2Loop because it acknowledges that environmental and economic considerations align with implementing circular economy strategies. In the case of the price-tag holder in the project scope, Primo is further motivated by an increased demand from the retailing industry to find EoL (End-of-Life) solutions. Primo sees an opportunity to recover the value of the material in price-tag-holders at the EoL. Moreover, they are working to increase the recycled content to have 30% of raw material from recycled or renewable sources by 2030. Primo is already looking into changing the input material for the price-tag-holders to PET due to its higher recyclability.

Opportunity

Plastic extrusion companies face future challenges related to increased policy regulations and material price fluctuations. Furthermore, the life cycle mapping shows that emissions related to raw material extraction are a hotspot.

The price-tag holder is a low-value product with little potential for offering additional services but a high potential for increased recyclability. Hence, the largest potential lies in implementing strategies for improved EoL treatment, which has also been requested by the end-users.

This presents an opportunity for Primo to embrace circular economy by implementing a takeback system. Besides promoting a reduction of waste and a responsible product lifecycle, such a model would also entail economic opportunities in the form of recovering material value. With the ongoing shift to the more recyclable PET, a pilot take-back system would align with the company's ongoing sustainability efforts and provide Primo with valuable insights and learnings.

Transition path

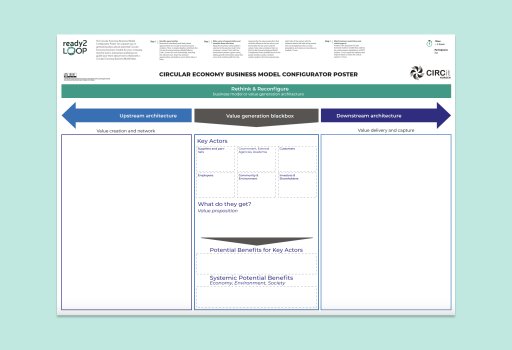

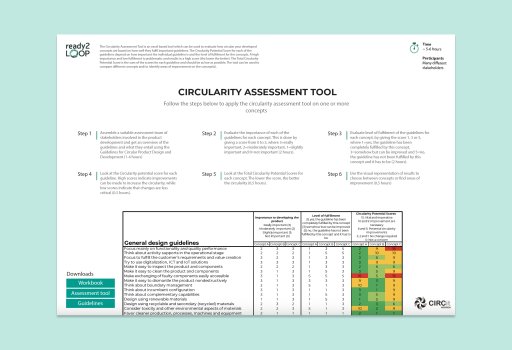

The prioritised dimensions for Primo were Take-back & End-of-Life Strategies and Strategy & Business Model Innovation. The first step in implementing a pilot project for a take-back system includes establishing an agreement within Primo and communicating the need for a take-back system in the future. The road mapping tool helped make a clear overview of the transition path, including critical activities, potential challenges and possible mitigation efforts.

Good communication over the value chain ( supplier - distributor- retailer ) is crucial to increasing the probability of a successful implementation of a takeback system. Primo, as a supplier, only collaborates with its upstream partners and is limited in further collaboration with the retailer (end-user) due to its distributor (customer) agreement. Primo only has contact with the distributor, so they must collaborate when finding a retailer willing to participate in a pilot project. Primo will also need to establish partnerships with recycling actors due to the technicalities of the material involved.

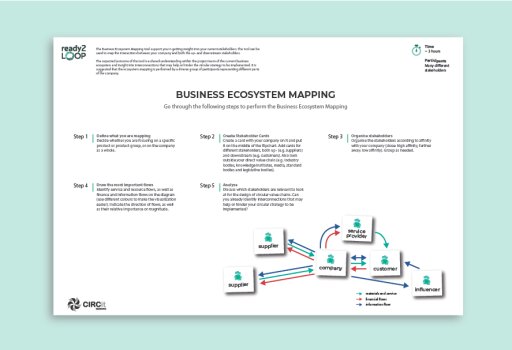

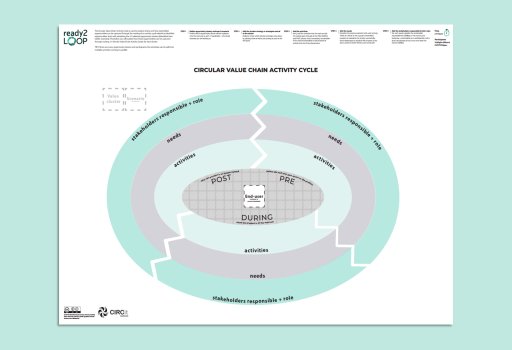

The road mapping tool shows the further steps and actors involved. Primos’ design and quality team would have to assess if the recycled plastic is suitable for new extrusions of price-tag holders, and hence the possibility of creating a closed-loop system. Throughout the pilot project, the sustainability team would have to monitor the stakeholders and processes to assess the outcome. Furthermore, the sales department within Primo would have to assess the pilot project and consider the economic risks and monetary flows and investigate possible incentives to ensure buy-in and future profitability. To make this assessment, it is advised to use the tool "circular value chain activity cycle" further as its purpose is mapping out the product’s journey, including the monetary flows and different stakeholders’ activities and responsibilities.

Outcome

By applying the tools in the context of planning the takeback pilot project, key aspects that need to be in place for the system to work and for Primo to become more circular were identified. Main insights include the need for collaboration with the key value chain actors and establishing new relationships. The road mapping tool provides insights for further planning by enhancing the company’s readiness by participating in the accelerator programme. Primo is on their way to achieving planning pilot implementation on the readiness scale in the Ready2Loop platform. By bringing the ideas into action, Primo will further enhance their readiness scale.

Implementing a take-back pilot project will allow Primo to minimise waste and recover the resource value at the EoL. Ultimately, the recovered material can be used to extrude new profiles. The pilot project is an important first step in implementing a closed-loop circular system for price tag holders.

Reflections

The accelerator program helped us understand Primo's current position in terms of circularity. The meetings with Primo provided valuable insights into opportunities and aided in identifying potential bottlenecks. One of the main takeaways is that Primo will need to establish new relationships and partners with other actors to implement a take-back system and find cross-value chain solutions.

Next step

Implement the learning from the pilot to other products and improve the design to enhance recyclability and prevent theft and the use of tape.

Increase communication through the value chain to increase value recovery at EoL.

Clear waste separation information at the user level: colour, engraved text, or code in the profiles to indicate to the user which polymer they are dealing with.

Reusable packaging: a foldable and sturdy box can be implemented and optimised for trucks/containers.

Micro-Accelerator. January 2024 - offered by ready2LOOP & DTU Course, Design for Circular Economy

Company

Primo Group