Exploring circular strategies for a prominent plastic producer

“The Accelerator program allowed us to learn and gain valuable input to improve our discussions on how to align our take-back activities with circular economy principles. This helps us to contribute to environmental sustainability and stay true to our commitment to responsible business practices.” Primo Group

Opportunity

Increased focus on plastic pollution has led to increased demand and expectations in the plastic industry by lawmakers, partners, customers, and consumers alike. Primo has taken responsibility for reducing environmental impact by investigating circular strategies since 2010. Primo is a global market leader in the field of plastic extrusion, and with their high turnover of plastic profiles, they are looking for opportunities within the circular economy.

Path

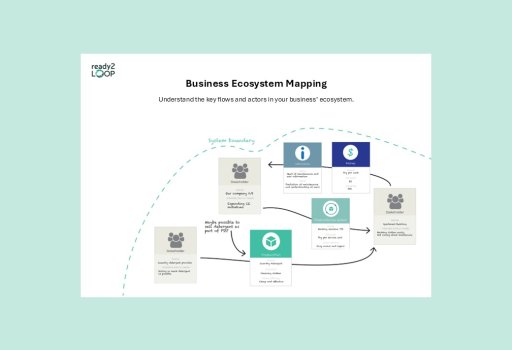

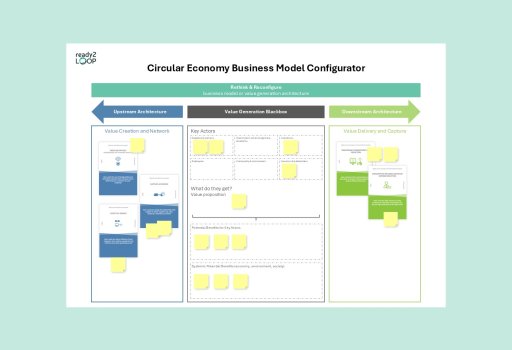

Primo's move to a circular economy began with a ready2LOOP Assessment, emphasising 'Takeback & End-of-Life Strategies' and 'Organisation.' After analysing current operations and sustainable initiatives, tools like 'Circular Business Model Configurator' identified a strong opportunity for a take-back system. 'Business Ecosystem Mapping' and 'Collection Archetype selection' solidified a robust take-back solution, presenting a promising circular business model for Primo's plastic profiles.

Outcome

Together with Primo, it was decided to enhance its circularity by implementing a takeback system. This involves an indirect takeback and packaging system, where a specialised service provider retrieves used profiles from retailers and returns the recycled materials to Primo. This approach offers several advantages: no direct customer contact with retailers is required, and the recycling process is handled by a company specialising in plastic recycling, which is more advanced than Primo. Overall, this option appears to be realistic and feasible.

Context

Primo is one of Europe’s leading specialists in producing polymer components from extrusion processes. They offer custom solutions for a wide variety of business areas, e.g., the medical industry, electronics, building construction, etc. They are known for the strength, versatility, lightweight, and durability of their high-quality products, and with their 60 years of experience, they deliver added value throughout their customers’ value chain.

Sustainability is a core value at Primo. Despite polymers and plastic extrusion products being their main business, they are committed to sustainability through their FUTURE FIT program, with specific sustainability goals and deadlines. They are driven to make this vision come true. They are part of Operation Clean Sweep and focus on avoiding plastic pellets, flakes and powder losses to the environment. To further its sustainability mission, Primo is now focusing on investigating opportunities within a circular economy.

Opportunity

The increasing focus on plastic pollution has raised the bar for the plastic industry as regulators, partners, customers, and consumers now have heightened expectations. As a responsible company, Primo has been actively exploring circular strategies to mitigate its environmental footprint.

Primo stands out as one of Europe's largest plastic extruders. This study focuses on their plastic profiles, especially price-tag holders designed for retailers. These products have a short lifespan (2-8 weeks), and there is no established End-of-Life procedure. With such a high turnover of plastic profiles, there definitely is an opportunity for a transition to a circular strategy that will benefit both sustainability and economics.

Transition path

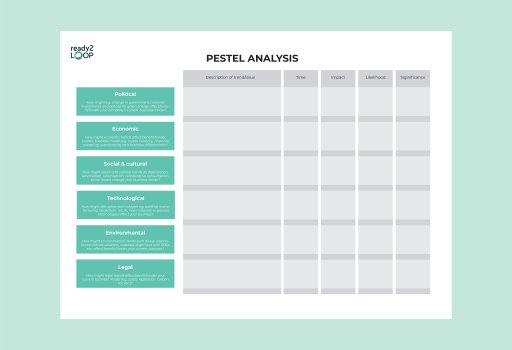

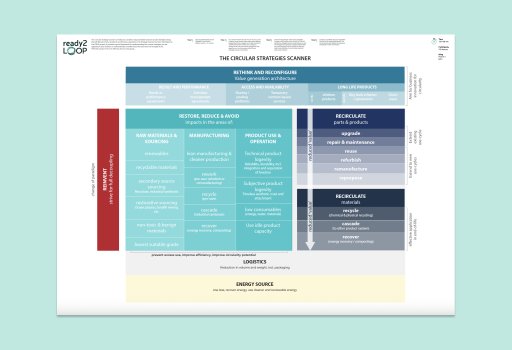

The transition path for Primo to utilise circular economy principles regarding their plastic profiles for convenience stores began with a mission to understand Primo’s current operations, business model, strategy, and existing sustainable initiatives. The focus was on the extruded plastic profiles used for price tags in convenience stores. After the initial screening and understanding of Primo, various circular strategy tools and methods were employed to analyse the company further. One such tool was the ‘Circular Strategy Scanner,’ which helped assess Primo’s current circular initiatives. Additionally, a PESTEL analysis of Primo was conducted to understand external factors that could impact the company.

With a strong understanding of Primo’s current circular and sustainable practices, the focus shifted to how Primo could become a more circular business. A Ready2LOOP Readiness Assessment was carried out and showed the prioritisation of ‘Takeback & End-of-Life Strategies’ and ‘Organisation’. Tools such as ‘Circular Business Model Configurator’ showed a strong opportunity for Primo to investigate a takeback system for their plastic profiles. A thorough use of' Business Ecosystem Mapping' was performed to understand the potential ecosystem around Primo in a take-back system. A solution for the products/material return to Primo had to be investigated to strengthen further and validate the takeback system. The tool ‘Collection Archetype selector’ was used to ensure the best possible solution had been selected.

The circular initiative resulted in a strong potential circular business model for Primo to investigate and incorporate within the scope of their plastic profiles sold to retail stores.

Outcome

Primo, a company that manufactures and sells plastic profile products, wants to improve its circularity. Investigation leading to three different take-back systems:

- A reverse take-back and packaging system that uses the distributor between Primo and retailers as an intermediary for returning profiles with their original packaging.

- A direct take-back and packaging reuse process, establishing a circular loop among Primo, the distributor, and retailers. Retailers would send the used profiles back to Primo.

- An indirect take-back and packaging system involving a service provider who retrieves used profiles from retailers and sends the recycled materials back to Primo.

After evaluating the three options, Primo chose the indirect take-back and packaging system. This system was chosen because it was the most feasible and realistic option. It did not require direct relations with retailers, and Primo could not yet recycle all its products.

Reflections

Implementing a circular design for a non-standardised product with a low value in terms of material consumption is very difficult. In particular, the product's price-sensitive market makes it difficult to find an economical and sustainable solution. The search for components that fulfil the requirements of takeback systems and for customers who are willing to pay a little more for a sustainable solution will be the decisive points in the implementation phase.

Next step

The next steps can be divided into several points:

Completing the planning phase by evaluating the project through a feasibility study. Is it truly economically feasible to introduce a take-back system and remain competitive?

Identifying key stakeholders, such as distributors, retailers, and recycling companies, who are willing to participate in a testing phase.

Start a test phase, e.g. for six months, with a specific retailer and recycling company that is willing to take on the profiles.

Evaluation of the test phase and further expansion of the take-back system throughout Europe.

Micro-Accelerator. January 2024 - offered by ready2LOOP & DTU Course, Design for Circular Economy

Company

Primo Group