End-of-Life Pilot of Solar Collectors in the Spanish Market

“BDR Thermea has gained valuable insights on how to improve our circular strategy. We are excited to explore the solutions suggested to reap the benefits of new technologies and services in addition to competitor advantage.” - Claudia Wagenfuhr Tridapalli, Sustainability Lead Engineer

Opportunity

BDR Thermea, a provider of heating and cooling solutions, is working to incorporate circularity into its business model. BDR Thermea has the opportunity to explore new End-of-Life solutions by initiating a project in Spain to take back used solar collectors produced by Fabrosolia, a company owned by BDR Thermea and a market leader. Since BDR Thermea's competitors offer limited circular economy solutions in this field, enhancing this aspect could give BDR Thermea a competitive advantage, appealing to various customer segments.

Path

With 80% of BDR Thermea's collectors manufactured at Fabrisolia in Barcelona, the focus is on solar thermal collectors in the Spanish market. The proposed approach involves a recirculation strategy, considering the condition of used products to enhance material conservation and reduce costs. The primary dimension of the proposed pilot is Takeback & EoL Strategies. This recommendation on the transition path and suggested tools may extend to other units if the pilot succeeds.

Outcome

Improving the End-of-Life options by working on the reuse of components can reduce the waste created by disassembled solar heating systems. Implementing a take-back system could provide BDR Thermea with functional components that could still be used in other systems, thereby reducing the costs of raw materials and new parts. Creating a new business model could establish new revenue streams, benefitting the company and generating other value for different customer segments.

Context

BDR Thermea, a global leader in heating and cooling systems, operates across eight countries with manufacturing sites in 11 locations, offering both conventional and eco-friendly solutions tailored to clients’ needs. Positioned at the forefront of the energy transition to sustainable thermal systems, BDR Thermea strategically emphasises integrating circular economy principles into its entire value chain. In 2022, an assessment of BDR Thermea indicated that a significant portion of their primary waste streams are currently being recycled to cut operational waste by 50%, set for 2025. BDR Thermea actively explores refurbishing solutions and acknowledges that achieving true circularity extends beyond immediate operations. By prioritising maintenance and installer training, the company embraces a holistic approach. A new take-back system business model could reduce material use and expenses, providing new End-of-Life solutions that align with their vision of achieving genuine circularity through standardised components.

Opportunity

The primary opportunity lies in addressing End-of-Life options while meeting customer needs by recirculating components and materials back into production after a quality assessment of the parts. The business model should be revised to incorporate the take-back of BDR Thermea parts. This can potentially reduce component costs and enhance the company’s marked image. However, it is crucial to factor in the costs of this initiative, either by adjusting the initial price or incorporating it through instalments over the Solar Collector lifetime. Exploring an End-of-Life pilot for solar collectors in the Spanish market is a viable option, given that 80% of BDR Thermea’s solar collectors are produced in Barcelona and distributed across Europe.

Transition path

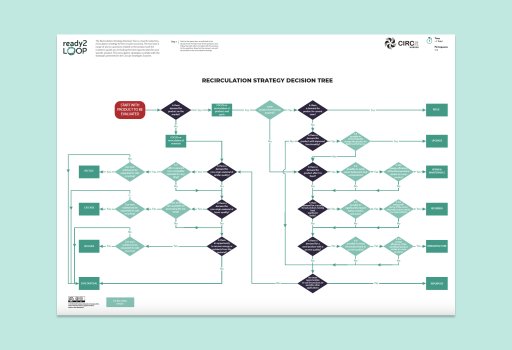

The company does not currently have a functioning End-of-Life and take-back strategy for their products. 80% of the collectors marketed under the BDR Thermea brand are manufactured by Fabrisolia, a company located in Spain. Therefore, End-of-Life strategies for solar collectors in the Spanish market were chosen as the transition path to trial circularity solutions within the company through a pilot. Furthermore, as the selected dimension was Take-back & EoL Strategies, the use of new materials could be reduced by taking back old heating systems. The state of the used products should then be taken into consideration when choosing the best recirculation approach, using components on new systems.

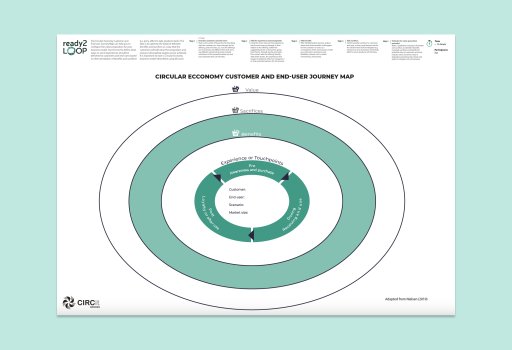

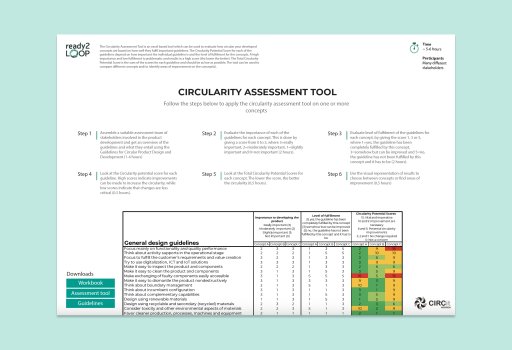

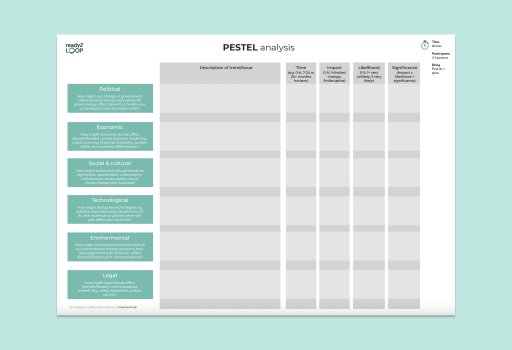

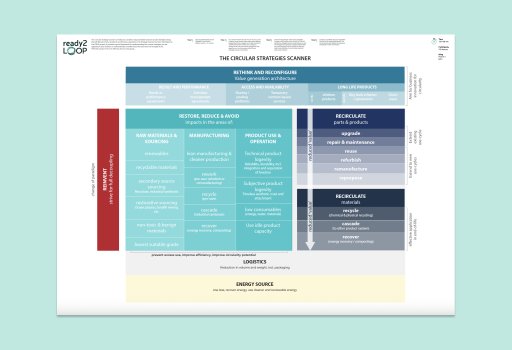

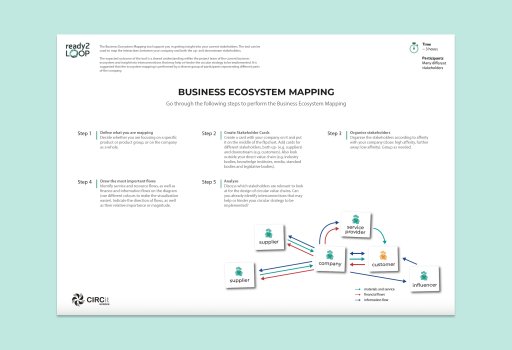

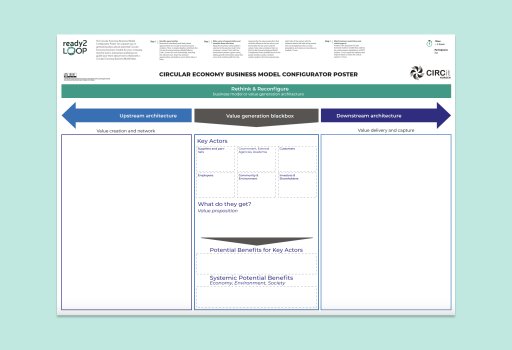

The PESTEL analysis underscores the business incentive for BDR Thermea to enhance circularity, address technology innovation, and align with ESG regulations. The sources of systemic waste mainly concern the product's EoL, as the waste from the manufacturing process is already being recycled. The Value Chain mapping identified profit-centric steps and offered a comprehensive overview of project stakeholders. The circular economy scanner narrowed the project scope, enabling a focused approach aligned with the company's needs. The CE business model configurator serves as a guideline in hotspot identification, facilitating a comprehensive transition plan. The circularity concept evaluation tool analyzed competitors' steps, while various take-back systems were identified through a separate tool. Two additional synthesis tools, focusing on EoL strategies and the value proposition for the business model, were selected based on the results of the readiness assessment. These tools are the recirculation strategy decision tree, which confirms the initial ideas selected as EoL strategies, and the Customer and End-User Journey Map, which provides insights into how the business model is connected to the customer.

Outcome

The improvement of End-of-Life options can enhance the quality of the service delivered to customers while increasing the circularity of the company. Used parts could be installed in new systems if they still work, increasing their lifetime and achieving savings on new components and using raw materials. The new business model, which includes the cost of servicing and end-of-life options at the initial price, could benefit the company while providing customer satisfaction. This could make them more willing to install BDR Thermea products, enlarging the company's customer segments. Piloting the take-back of Fabrisolia solar collectors could also spark similar projects involving other business units across the company. This could lead to other trials with different products and potentially reusing all components within the same system, creating a complete second-hand solar heating solution. New business opportunities might arise as a result of increasing profits and environmental awareness.

Reflections

BDR Thermea manufactures traditional and sustainable heating solutions, recycling all material waste generated during their operations, except at the End-of-Life stage. The Circular Economy unit has not been established yet, but the company is open to new opportunities. BDR Thermea aims to address hotspots through innovations that could enhance the circularity options of their products. The questions raised over the project can spark new ideas and contribute to the company's growth once developed by internal stakeholders.

Next step

End-of-life options should be implemented by establishing a straightforward process and a team to organise these activities across all business units. The company's R&D section and the finance team should assess the feasibility of the suggestions and offer some changes to the proposed insights to better suit the company and market requirements. All employees within BDR Thermea should be trained on the circular economy so that they can initiate new solutions within their departments.

Micro-Accelerator. January 2024 - offered by ready2LOOP & DTU Course, Design for Circular Economy

Company

BDR Thermea