Supporting DIY paint customers to eliminate waste at end-of-use

"The readiness assessment was a great way to engage key stakeholders and to help us get great insights into our current readiness as an organisation" – Head of Manufacturing, Martin Hammerich Lund

Opportunity

Using a systematic innovation approach to avoid the waste of paint at end-of-life for DIY customers.

Path

How can 'Use, support and maintenance' as a focus area can trigger innovation for improved environmental performance and customer experience?

Outcome

Insights to PPG of the impacts throughout a product's life cycle and the customers' decision journey, plus scenarios to support elimination of environmental effects during the life cycle.

Context

PPG is a large global manufacturer of coatings that protect and beautify the world with products such as paint and coatings for the building-, aerospace- and automotive-industries. PPG's Danish manufacturing site, situated in Søborg, has improved its environmental performance a great deal during the last decade and the company is motivated to continue this effort, going forward. In the coming years, the paint industry faces a change in legislation when it comes to both additives in the paint and in increased producer responsibility, when it comes to closing the loop on packaging.

Opportunity

The Danish production site has continuously developed and improved its environmental performance over the years and has become the leading factory in environmental performance among the company's many global sites. This is also the reason PPG saw an opportunity to further strengthen its performance through the concept of Circular Economy. The company collaborated with ready2LOOP to explore opportunities to implement circular strategies that could specifically contribute to less paint waste at end-of-use for their DIY customers. This way, PPG identified new ways to reduce resource waste and environmental impact.

Transition path

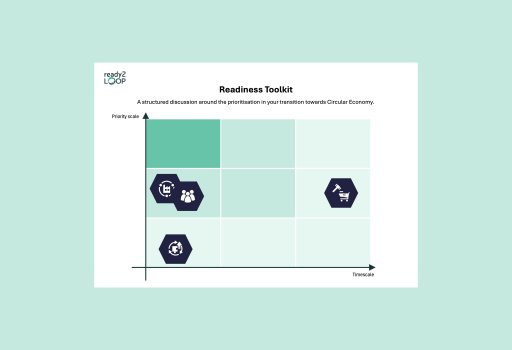

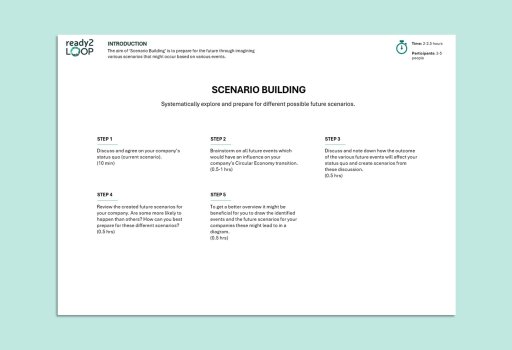

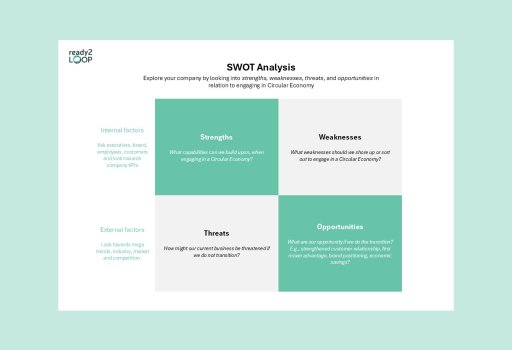

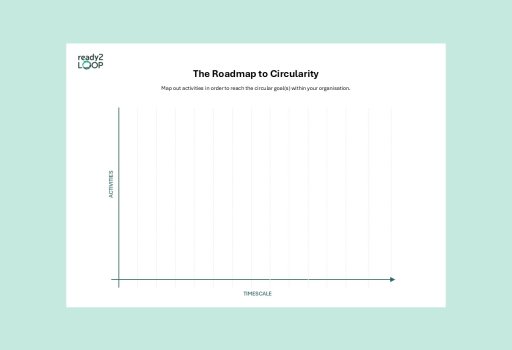

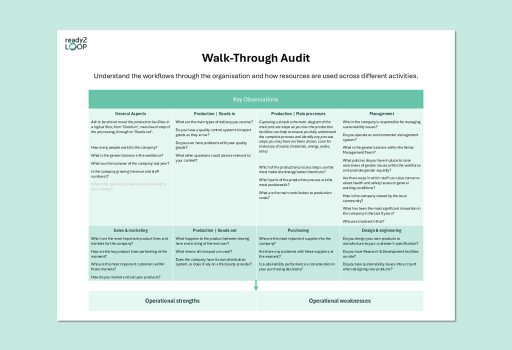

The first step for PPG was to use the ready2LOOP readiness assessment and readiness toolbox, where the readiness dimension 'Use, support & maintenance' was chosen as a focus area, aiming to influence PPG's approach to 'Innovation of strategy & business model'. The tool 'Circular Economy Prioritisation Matrix' was used to create a logical and structured prioritisation of various activities in the company, contributing to an overview and internal alignment within the company.

Outcome

Using the readiness assessment, PPG initiated a discussion about their circular economy strategies and chose a transformation route to focus on. The focus on the dimensions 'Use, support & maintenance' and 'Innovation of strategy & business model' resulted in concrete projects that supported PPG to prepare advice to its DIY customers in the purchasing situation, regarding the most appropriate products and quantities, their cleaning, and correct disposal. All of these efforts will contribute to reducing PPG's environmental footprint through reduced resource waste.

Reflections

During the process, PPG used the ready2LOOP tools, primarily to assess their readiness for the transition to a circular economy. They were supported in choosing a focus area. The choice of the readiness dimension 'Use, support & maintenance' resulted in the conceptualisation of solutions for their DIY customers that can reduce waste and environmental impact.

We asked Head of Manufacturing, Martin Hammerich Lund to reflect on how the ready2LOOP methodology helped PPG to prepare themselves for the circular transition. "From working with tools and methods supporting systematic innovation within a circular economy has given a good insight into the different touchpoints, that are crucial to support the users in if we want a more sustainable system for paint." was Martin's response.

Next step

PPG and other companies in the paint industry are entering new times, where regulations require them to implement circular strategies. The first steps have been taken, but there are still plenty of opportunities for PPG to become a first-mover, and there are many tools on the ready2LOOP platform that can support them in developing new circular strategies.

Company

PPG Coatings Danmark A/S